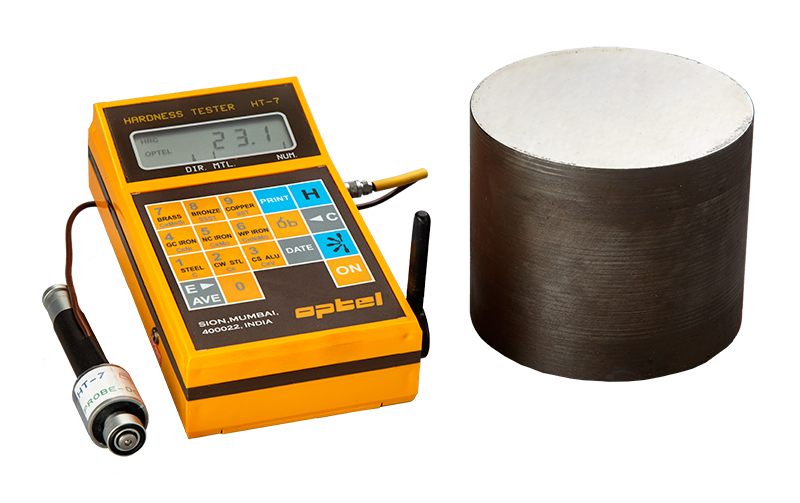

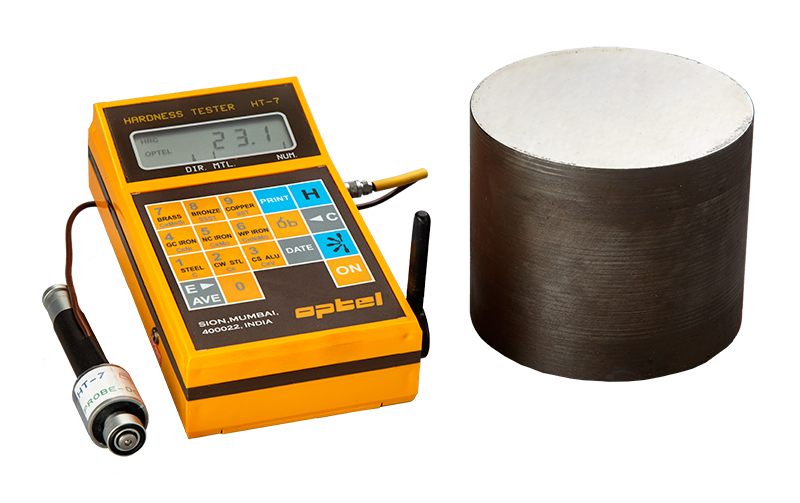

HT-7: Portable Hardness Tester

HT-7 is a hardness tester which uses an impact body with a tungsten carbide tip, which is impelled by a spring onto the metal surface. The ratio of rebound velocity to the impact velocity is proportional to the hardness of the sample. The instrument converts this into a hardness value in various scales.

HT-7 is a hardness tester which uses an impact body with a tungsten carbide tip, which is impelled by a spring onto the metal surface. The ratio of rebound velocity to the impact velocity is proportional to the hardness of the sample. The instrument converts this into a hardness value in various scales.

| Application Areas |

In situ hardness measurement of:

- Dies and moulds

- Large and heavy work pieces

- Shafts

- Bearings

- Lab measurements on special forms

- Identification of materials by measuring strength of material

|

| Range |

See Table 1 |

| Strength of material |

See Table 2 |

| Impact Device |

Tungsten Carbide ball |

| Measuring Area (Aperture) |

|

| Accuracy |

|

| Operating Temperature |

10° C to 50° C |

| Battery |

4 penlite cells (50-60 hours) |

Dimensions

H x W x D (in mm)

|

150 H x 80 W x 45 D |

| Weight (with battery) |

365 grams |

| Steel |

18-68.5 |

60-99.5 |

93-651 |

83-976 |

32-99.5 |

| C.W. Tool Steel |

20-67 |

|

|

80-898 |

|

| Cast Aluminium |

|

|

30-159 |

|

|

| Grey Cast Iron |

|

|

93-334 |

|

|

| Nodular Cast Iron |

|

|

131-387 |

|

|

| W.P Iron |

HL ONLY |

| Brass |

|

14-95 |

40-173 |

|

|

| Bronze |

|

|

60-290 |

|

|

| Copper |

|

|

45-315 |

|

|

Strength of Material Table 2

| 1 |

Carbon Steel |

350 – 710 |

374 – 1670 |

| 2 |

Cr – Steel |

500 – 730 |

707 – 1829 |

| 3 |

CrV – Steel |

500 – 750 |

704 – 1980 |

| 4 |

CrNi – Steel |

500 – 749 |

763 – 1999 |

| 5 |

CrMo – Steel |

500 – 730 |

721 – 1813 |

| 6 |

CrNiMo – Steel |

540 – 730 |

844 – 1869 |

| 7 |

CrMnSi – Steel |

500 – 750 |

755 – 1993 |

| 8 |

Super Strength Steel |

630 – 740 |

1180 – 1936 |

| 9 |

Stainless Steel |

500 – 710 |

730 – 1676 |

HT-7 is a hardness tester which uses an impact body with a tungsten carbide tip, which is impelled by a spring onto the metal surface. The ratio of rebound velocity to the impact velocity is proportional to the hardness of the sample. The instrument converts this into a hardness value in various scales.

HT-7 is a hardness tester which uses an impact body with a tungsten carbide tip, which is impelled by a spring onto the metal surface. The ratio of rebound velocity to the impact velocity is proportional to the hardness of the sample. The instrument converts this into a hardness value in various scales.